Among the greenhouse gases contributing to global warming, carbon dioxide stands out as the most prevalent emission from human activities. Experts advocate for not only a significant reduction in fossil fuel consumption but also the active extraction of CO2 from our atmosphere. However, existing carbon capture technologies tend to be costly and energy-intensive, requiring effective carbon storage solutions.

Researchers from Stanford University have introduced an innovative and surprisingly straightforward approach: leveraging the capabilities of rocks.

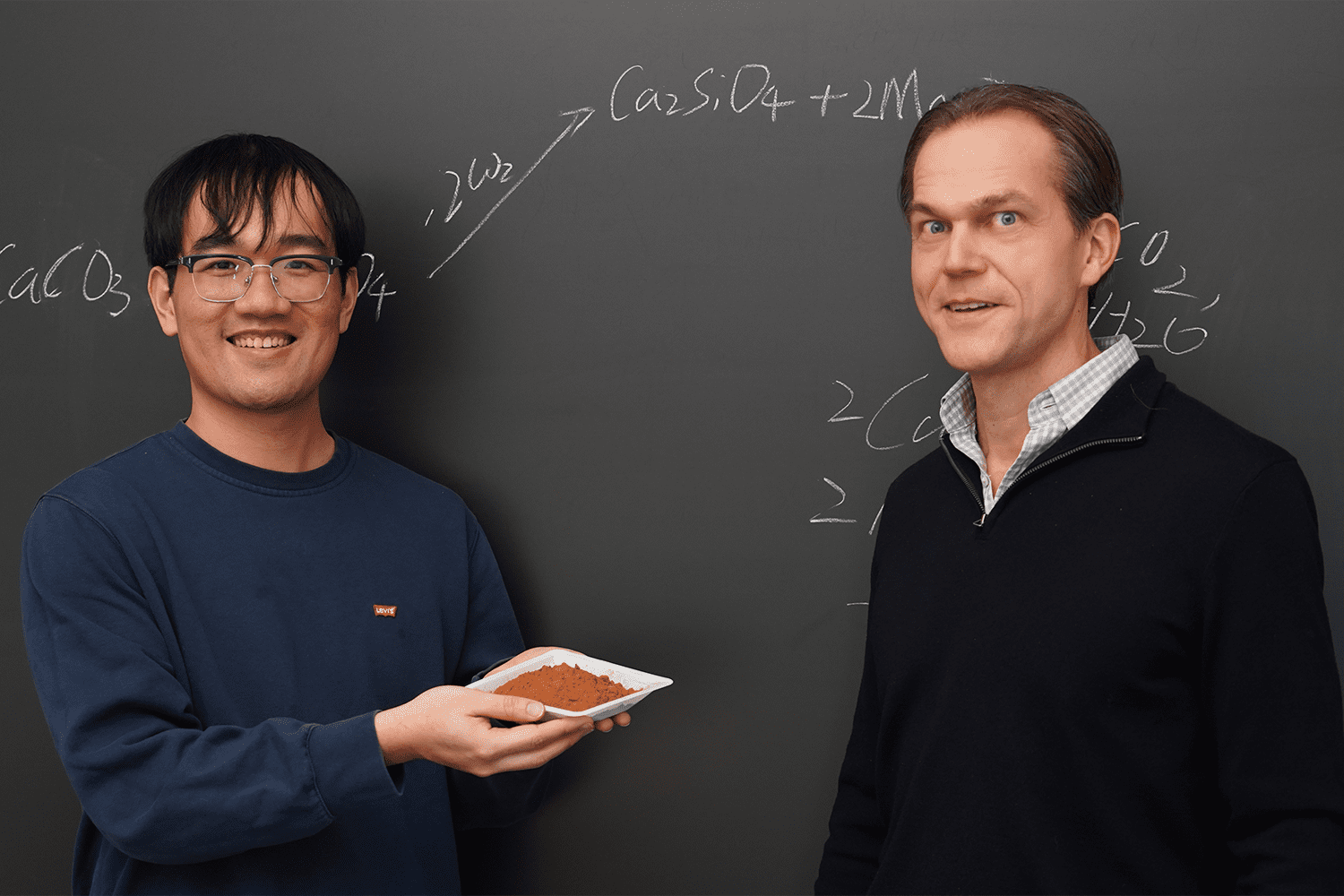

Indeed, chemists Matthew Kanan and Yuxuan Chen at Stanford have devised a method that utilizes heat to transform minerals into materials that can absorb CO2 permanently. Their research, recently published in the journal Nature, outlines a process that is both practical and cost-effective. Furthermore, the minerals developed by Kanan and Chen could address a common agricultural need, achieving dual benefits.

“The Earth has an endless supply of minerals that are capable of removing CO2, but they lack the reactivity needed to effectively counter human greenhouse gas emissions,” stated Kanan, the study’s senior author, in a Stanford news release. “Our research addresses this challenge in a uniquely scalable manner.”

For years, scientists have explored methods to expedite the natural absorption of CO2 by certain rocks, a slow process called weathering that can span centuries. Kanan and Chen have seemingly unlocked the potential to accelerate this process by converting common slow-weathering minerals, known as silicates, into minerals that weather more rapidly.

“We envisioned a novel chemistry to activate the inert silicate minerals through a straightforward ion-exchange reaction,” Chen explained. Ions are charged particles that play a crucial role in chemical reactions. “The effectiveness of our method exceeded our expectations.”

Taking inspiration from cement production, where limestone is heated in a kiln to form calcium oxide, the researchers applied a similar technique by using magnesium silicate instead of sand. Through the application of heat, the magnesium silicate converts into reactive minerals like magnesium oxide and calcium silicate, which are known to weather rapidly.

“Our process acts as a multiplier,” Kanan noted. “We start with one reactive mineral, calcium oxide, and an inert magnesium silicate, leading to the generation of two highly reactive minerals.”

To validate their findings, Kanan and Chen exposed wet calcium silicate and magnesium oxide to the atmosphere. They discovered that these minerals transformed into carbonate minerals—a product of weathering—within a matter of weeks to months.

“Imagine the potential of applying magnesium oxide and calcium silicate across extensive land areas to extract CO2 from the air,” Kanan said. “One promising application we are currently testing is incorporating these materials into agricultural soil.” This method could also benefit farmers who typically use calcium carbonate for liming when soil acidity is too high.

“Using our product would negate the need for traditional liming, as both components are alkaline,” Kanan elaborated. “Moreover, as calcium silicate weathers, it releases silicon in a form that plants can utilize, enhancing crop yield and resilience. Ideally, farmers would invest in these minerals due to their productivity benefits and soil health improvement—alongside the added advantage of carbon removal.”

Research suggests that approximately one ton of magnesium oxide and calcium silicate could absorb an equivalent amount of CO2 from the atmosphere. This figure even accounts for the CO2 emissions generated during the kiln process, which uses less than half the energy of conventional carbon capture technologies.

However, scaling this solution to achieve significant impact would demand millions of tons of magnesium oxide and calcium silicate each year. Nevertheless, Chen highlights that if estimates regarding natural magnesium silicate reserves, such as olivine and serpentine, hold true, they could potentially absorb all human-emitted atmospheric CO2—and even more. Additionally, these silicates could be sourced from mining byproducts.

“Our society has already mastered the production of billions of tons of cement annually, with kilns operating for decades,” Kanan asserted. “Leveraging this knowledge and infrastructure, we can clearly advance from laboratory discoveries to large-scale carbon removal.”