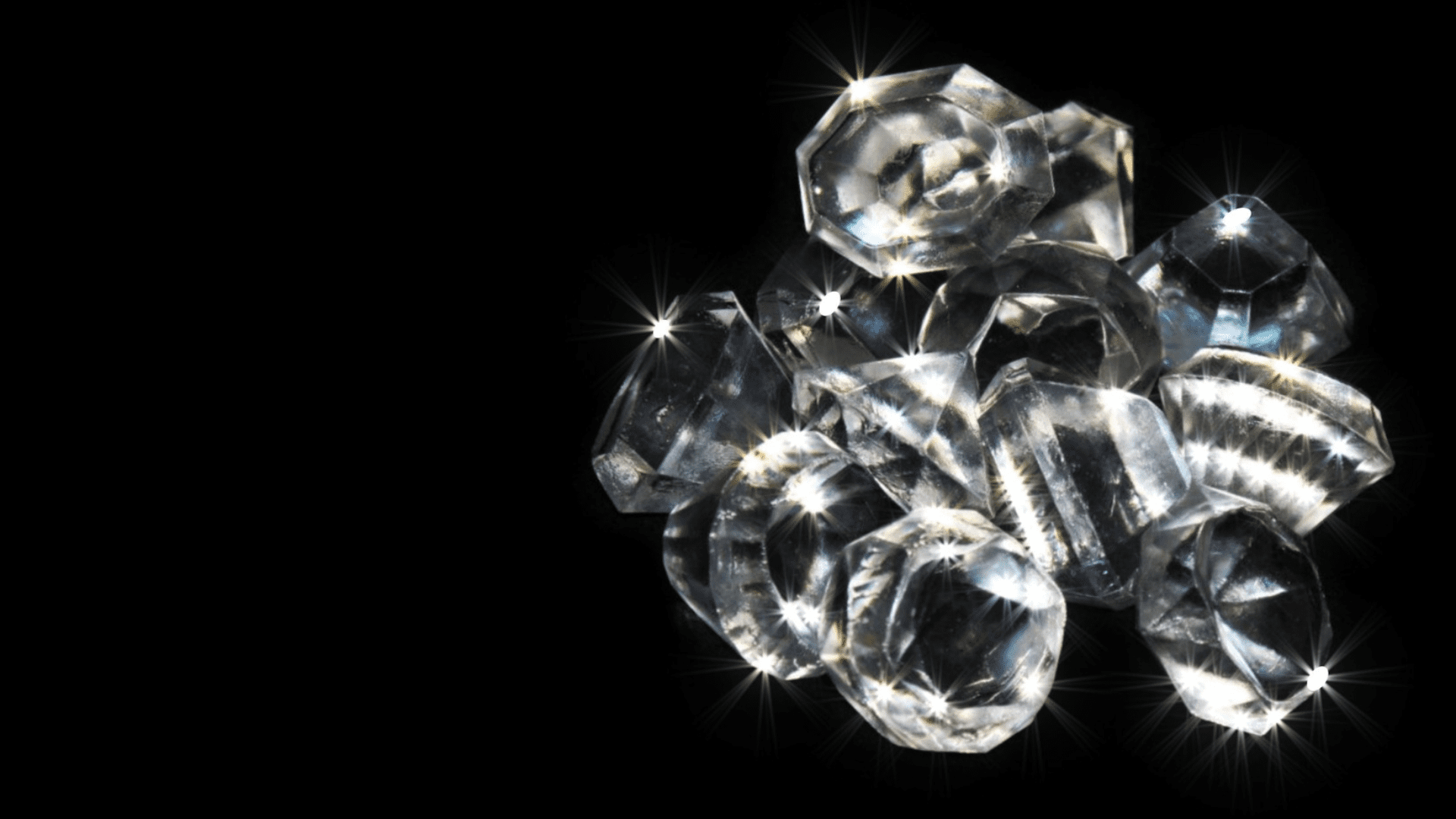

A team of researchers from two Chinese universities has successfully developed an extraordinary lab-created diamond, dubbed ‘super diamond,’ which boasts impressive strength and surpasses the natural diamond’s hardness by several times.

This significant advancement in diamond synthesis has exciting implications for various industries since diamonds are already integral to cutting and polishing applications. Notably, while most natural and synthetic diamonds exhibit a cubic crystal structure, the ultra-hard variant identified as lonsdaleite features a hexagonal crystal form.

Historically, the hardest diamonds could only be sourced from impact craters, which account for their rarity and diminutive size. However, researchers from Jilin University, under the leadership of Liu Bingbing and Yao Mingguang, alongside Zhu Shengcai from Sun Yat-sen University in Shenzhen, discovered a new structural phase called ‘post-graphite phase’ within graphite. This novel structure transforms into a hexagonal diamond when subjected to high pressure and extreme heating conditions. Their findings were recently published in the esteemed journal Nature Materials.

Creating Pure Hexagonal Diamonds from Graphite

The first instance of ultra-hard diamonds, known as lonsdaleite, was identified in the Canyon Diablo meteorite in Arizona back in 1967. Although replicating this diamond artificially has proven difficult, the Chinese research team has established a viable method for synthesizing high-quality, well-defined hexagonal diamonds directly from graphite, as reported by the South China Morning Post.

The study emphasizes that this synthetic diamond stands out for its exceptional quality, boasting hardness levels that are 40% greater than those of natural diamonds. Furthermore, it exhibits superior thermal stability compared to nanodiamonds, which are less than 100 nanometers in size. The researchers assert that the remarkable thermal stability and ultra hardness of the hexagonal diamond indicate its immense potential in industrial applications. They also highlight that their research provides crucial insights into the process of transforming graphite into diamond under conditions of increased pressure and temperature, paving the way for practical applications involving this unique material.

Previous Developments in Hexagonal Diamonds by US Researchers

This achievement is not the first of its kind in laboratory settings. A group of scientists in the United States previously reported in 2021 that they had engineered hexagonal diamonds large enough to analyze their stiffness using sound waves.

Co-author Travis Volz, a postdoctoral researcher at Lawrence Livermore National Laboratory, noted the wide-ranging potential of this lab-crafted material across various sectors, particularly highlighting its applications where advanced material properties are essential.

In their findings, the American researchers suggested that hexagonal diamonds might possess greater hardness than traditional cubic diamonds, positioning them as a superior choice for applications such as machining and drilling.

One researcher from the US team further speculated that these unique hexagonal diamonds could find their way into the market for engagement rings in the future, offering a compelling alternative to conventional diamonds due to their distinctive attributes.

Additionally, Chinese scientists have made notable strides in diamond research, particularly in exploring the properties of these materials. Last year, a collaboration involving Zhengzhou University, Henan Academy of Sciences, Ningbo University, and Jilin University led to the successful development of diamonds that can conduct electricity, showcasing the versatility and innovative potential of diamond materials.